JEN JIANN Machinery

Adhere to quality, sincere service and professional manufacturing

Who We Are

JEN JIANN One-stop integrated service

From routine processing business to hard-to-find surface treatments, as well as tedious packaging and shipping, customers no longer need to run around looking for various manufacturers.

Through our rich experience, we can give you the most efficient manufacturing method, provide you with the best product quality and reasonable price services!

Our company is conducting ESG carbon inventory operations in collaboration with Hungkuang University of Science and Technology.

We aim to move toward environmental sustainability and actively practice our low-carbon mission, hoping to contribute positively to society.

Service

Integrated services

One-stop services for various needs, including shaping, surface treatment, hardness treatment, and packaging assembly.

Routine operations

Material intake, processing, grinding, heat treatment, and discharge.

Surface treatment

Blackening, phosphating, sandblasting, and anodizing.

Logistics and transportation

Assembly, packaging, and shipping.

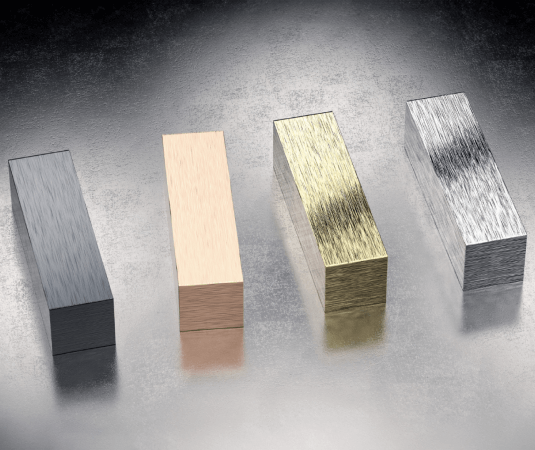

Material processing

Common metals such as copper, aluminum, iron, hardened alloy steel, cast iron, stainless steel, and more.

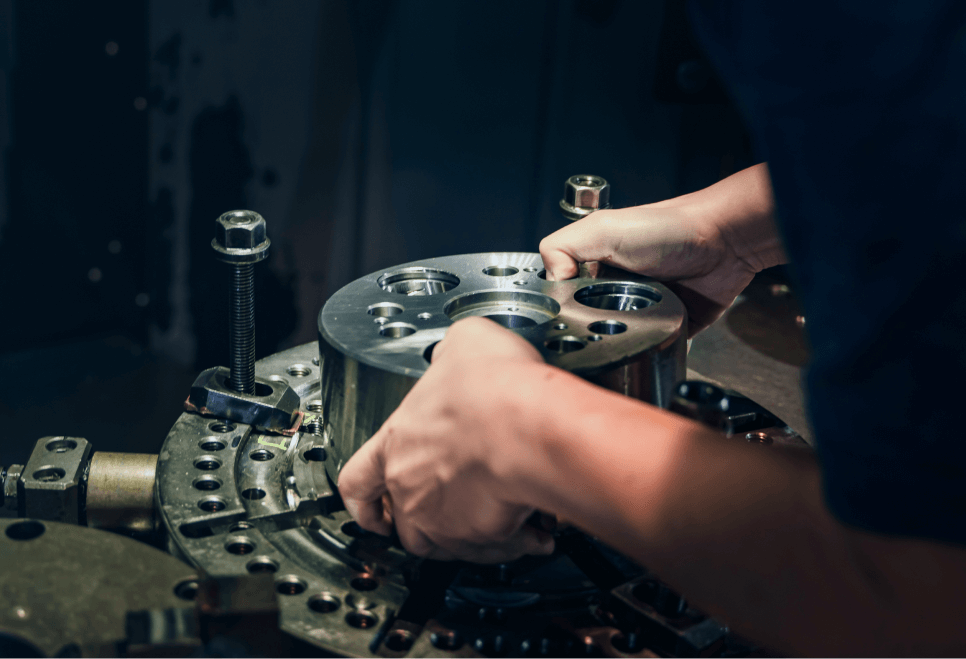

General parts processing

Hardened alloy processing

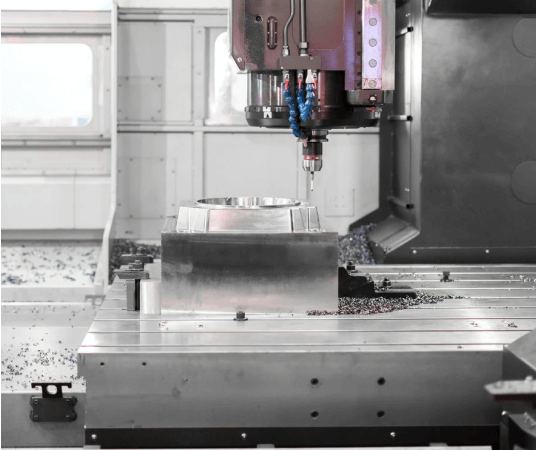

Mold processing

Decorative material processing

Groove grinding

Feature

真健服務特色

Capable of processing various materials.

In addition to commonly used materials such as copper, aluminum, and iron, we can also process more challenging materials like hard alloys, cast iron, and stainless steel.

Large workbench surface

A two-meter-wide CNC workbench surface can easily accommodate various styles of medium to large components, ensuring that your needs are well accommodated.

Diverse Services

We offer a range of services including material recommendations, parts manufacturing, mold production, medical equipment manufacturing, groove grinding, and assembly services, so you don’t have to search elsewhere.

Integrated Services

We provide a one-stop service that encompasses material selection, surface treatment, hardness treatment (heat treatment), grinding processing, and packaging and shipping. This allows customers to avoid the hassle of searching for qualified vendors for subsequent operations.

Rapid Prototyping Needs

We offer customized services to help clients rapidly prototype their requirements, covering a variety of materials, performance specifications, and price ranges to meet diverse customer needs.

Collaboration email

Various service items / Collaboration inquiries

Feel free to contact us at any time.

Online consultation

@xxx

Phone contact

(+886) 4-23500167